May 24th 2023

High efficiency thermal cleaning unit suitable for the Oil & Gas industry

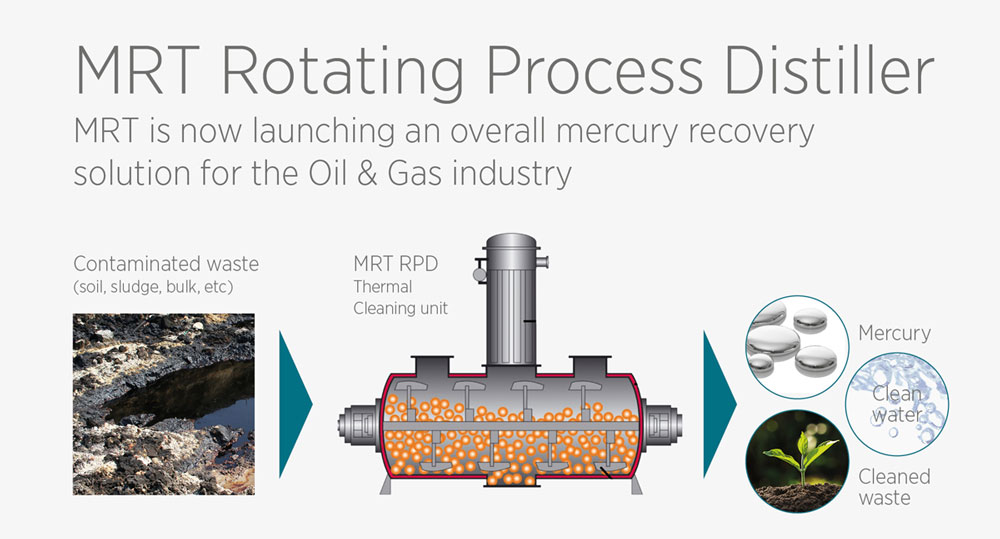

The MRT RPD uses thermal cleaning technology to separate Mercury from contaminated material in a safe and energy efficient way. It is built on site and designed for 24/7 operation. The MRT RPD unit is particularly suitable when processing large volumes, such as contaminated soil, drill mud, sludges, etc.

The possibility of transporting dangerous cases for decontamination is becoming increasingly limited. On-site remediation with MRT RPD is often a better option, both in terms of environment, safety, overall economy and energy efficiency. Other advantages of a site-built facility are that size and capacity can be adapted based on estimated needs.

Operation and decommissioning

Whether in terms of ongoing operations or decommissioning, Mercury is present in all aspects of the Oil & Gas industry. MRT System are experts in technology and solutions for processing Mercury contaminated material in a safe and efficient way.

Mercury has a considerable impact on the Oil & Gas industry. The presence must be predicted in all processes, measured and assessed in a safe manner. From exploration, drilling, transport and refining to decommissioning and recycling of oil and gas facilities.

Thermal cleaning vs Rotary Kiln

Solutions most often compared to the MRT RPD solution is technology based on usage of Rotary Kiln. The main difference in these two technologies is that the RPD operates under vacuum hence and requires much less energy during the process to gasify hydrocarbons and Mercury. For installations up to 10 tons per hour energy consumption using rotary kiln concept normally is 3 times bigger (up to 10 times for older technologies). Cost of operation of rotary kiln is at further disadvantage when adding the list of wear parts like seals, filters, bearings etc.

Advantages of RPD compared to rotary kiln can be summarized in: lower energy consumption, lower cost of operation, much smaller carbon foot print, more controlled environmental impact, more flexible in which material can be treated and more controlled outcome of depollution.

It all starts at our Test Center

MRT Test Center is truly unique because we can carry out all stages from sample analysis in our laboratory to live full scale testing. For MRT clients to feel secure in their investment it is wise to make sample testing as part of the evaluation process. Firstly, proof is given that the desired result can be achieved. Secondly, valuable data regarding anticipated process times and energy requirements will be given to establish need for capacity and expected operating cost.

How to handle large objects

Remediation of large structures and piping systems from Mercury is a big challenge. With an increasing number of installations to be decommissioned in the Oil & Gas industry, the question of how to treat areas contaminated with Mercury becomes more and more pressing. How to prevent danger to people working in decommissioning and how to prevent pollution of the greater environment is a key question. At MRT we have access to world leading equipment able to scale of the surface containing Mercury and other deposits leaving the structure clean and possible to handle in a safe way. The removed material including Mercury can be processed in a MRT Batch Process Distiller eliminating danger to people and the environment.

How to decimate tons to kilos

Besides the safety aspects, the main benefit with the MRT Concept is decimation of weight and volume. Why send hundreds of tons to disposal when you can decimate it to a few kilos? Patrick Strandqvist gives this vivid illustration: “An example from another industry shows that 200 tons of bulbs can be reduced to 1 litre of pure mercury. If we compare the cost of sending 200 tons of contaminated waste or 15 kg of mercury to disposal you quickly realize that there are large profits to be made.”

Do you want to find out more?

Please contact Patrick Strandqvist for further information.